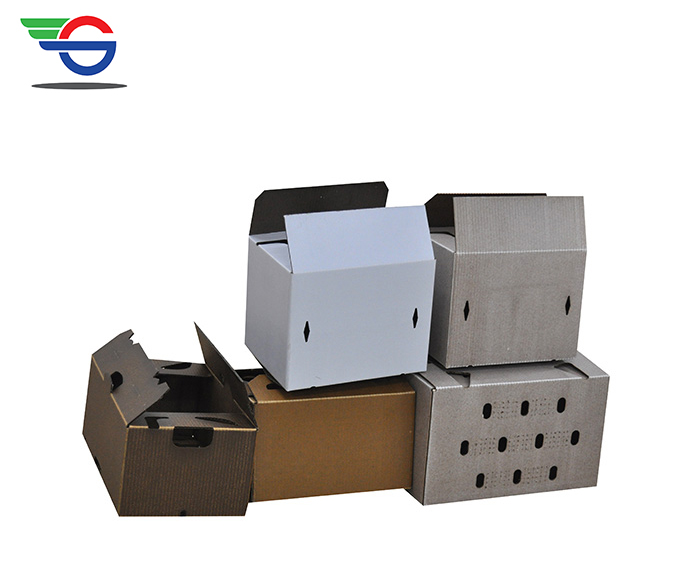

The first packaging color box will develop towards individualization and quality, because many high-end products now require exquisite packaging color boxes to package high-end products. Exquisite color boxes can not only protect the products, but also serve as a This kind of advertising media plays a role in promotion, and even some personalized packaging color boxes can attract customers' attention. The most common wine packaging and tea packaging are very delicate packaging color boxes.

Qualified carton products start from the correct structural design. The designer must not only truly understand the customer's intention, but also be familiar with the subsequent processing technology. Only in this way can the customer's intention be transformed into a qualified product and the subsequent processing of the product can be ensured smoothly. Designers must understand the nature, shape, size, weight of the contents, the arrangement of the contents, transportation methods, stacking methods, storage environment, transportation routes and time, carton types and materials, etc. before designing.

The production process of the packaging color box of the carton printing factory mainly includes: First, the product is designed. At this stage, the designer and the customer coordinate and cooperate to design and select the material of the packaging color box according to the requirements and appearance of the product. Second, hand over the designed product documents to a printing plant, and the printing plant will send the film with the film company. After the third printing plant receives the film, it will start to determine the printing according to the size of the film and the material and color of the paper. The fourth production of the knife mold needs to be determined according to the template and the printed semi-finished product. A good knife mold determines the appearance and shape of the color box. The mounting hole is mainly used on the hole box. According to your requirements, choose the hole paper to use a special machine to glue. Together. Fifth, beautify the appearance of the packaging color box, including laminating, bronzing, UV, oil polishing and so on. Sixth, the color box is die-cut to form the basic pattern of the color box. Finally, the packaging color box is adhered to the fixed connection parts of the color box according to the model or design pattern.

没有了!

没有了!